Mineral Technologies Inc. - MODSIM

2010年10月27日 MODSIM™ simulates integrated flowsheets that can include: crushing (jaw, giratory and cone crushers, high pressure rolls) grinding (AG, SAG, Rod and Ball

Guidelines for mineral process plant development

2021年6月24日 This paper presents guidelines for studies required for the development of mineral processing facilities from initial feasibility studies through to commissioning.

Mineral Processing Plant Design

2024年6月11日 Mineral Processing Plant Design 学分: 2 课时: 32 课程章节 1 第一单元 提示框 取消 进入课程 提示框 确定要报名此课程吗?确定 取消 京ICP备10040544号-2 ...

Review on advances in mineral processing technologies

2022年4月1日 The extraction of critical metals in a circular mining system involves four main steps: mineral processing, metal extraction, metal recovery, and residue

Mineral Processing Plant Design, Practice, and

2002年1月1日 The paper discusses the special mixing requirements for Metallurgical Plant Design and outlines the problems associated with the agitation in Mineral Processing Industry today.

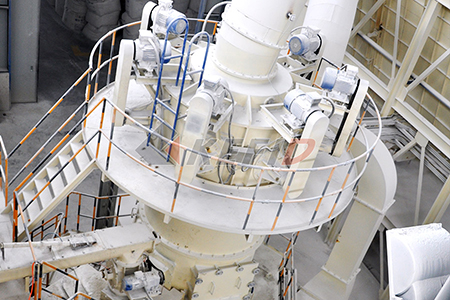

Mineral processing technology Engineered

Engineering design of process plant technology. We design and engineer world-class mineral processing technology tailor-made for your operations. For one complete solution across all project stages – customers choose

Mineral processing plant design, practice, and control :

USIM PAC 3: Design and Optimization of Mineral Processing Plants from Crushing to Refining

Mineral processing plant design, practice and control.

2016年3月17日 The useful information included in these proceedings will serve as an up-to-date aid for university-level professors and students in plant design courses; reference

Mineral Processing SpringerLink

2023年6月7日 Mineral processing is the process in which chemical or physical methods are used to separate the useful minerals in the ore from the useless minerals (usually called gangue) or hazardous minerals, or to separate multiple useful minerals. In the early years, mineral processing was called mineral concentration or mineral engineering in China.

Mineral Processing Plant SpringerLink

2023年5月3日 The production in mineral processing plant is a continuous process from delivery of crude ore to the plant, then to delivery of concentrate from the plant. The operation steps of mineral processing consist of different workshops or sections. These steps include crushing or screening, ore grinding or classification, separation,

Mineral Processing Plant Design, Practice, and Control (2

Mineral processing plant design, practice, and control proceedings by Mineral Processing Plant Design, Practice, and Control Conference (2002 Vancouver, B.C.), October 2002, Society for Mining Metallurgy Exploration edition, Hardcover in English

Optimizing mineral processing operations - Rhosonics

2023年5月10日 Mineral processing plants process minerals extracted from ore deposits. The design phase begins after the feasibility studies when engineers make choices based on anticipated production volumes. They size the plant's design, equipment, and piping according to these production volumes. This design must be suitable to withstand the

Mineral processing plants AFRY

4 天之前 Based on our breadth of knowledge, we can help clients at every step and in any scale of a project, from exploration to mining and minerals processing to further beneficiation, smelting and end-product refining and manufacturing to end-of-life recycling. AFRY is a European leader in engineering, design, and advisory services, with a global

Mineral Processing in Bioreactors: Fundamentals and Design

2.1 Metallurgical Unit Operations. Bioreactor design for hydrometallurgy and mineral processing requires consideration of the entire mineral processing system. Different unit operations may be involved before and after bioreactor operation (Fuerstenau Han, 2009), although bioreactors in mineral processing generally occur in the final stages of the

Mineral Processing: An In-Depth Guide - JXSC

2024年2月23日 11:46 am. Mineral processing is a key activity in the mining world, focusing on boosting the worth of raw minerals pulled from the earth. This crucial step turns the dug-up ores into cleaner and more concentrated versions that are ready for more use. By using both physical and chemical methods, mineral processing separates good, useful minerals ...

Strategies for instrumentation and control of flotation circuits

Strategies for instrumentation and control of flotation circuits. Steady state simulation is now widely used for the design and optimisation of mineral processing plants. One of the most difficult unit operations to simulate in mineral processing is flotation. There are two main reasons for this. Firstly, the flotation circuits are made up of a ...

Mineral Processing Plant Design Construction Example

2016年6月2日 The jaw opening is maintained at 1″. The crusher discharge, along with the grizzly undersize, is transported on a 14″ x 65′ conveyor with a slope of 4 3/8″ per foot at 150 feet per minute to the fine ore bin. The conveyor is powered with a 2-Hp., 1200-r.p.m., fan-cooled, totally enclosed ball bearing motor.

Guidelines for mineral process plant development

2021年6月24日 Keywords: Mineral process plant, Metallurgical testwork, Engineering and cost studies, Feasibility studies This paper is part of a special issue on Metallurgical Plant Design and Operating Strategies Introduction The continuing rapid rise in metal prices has resulted in an unprecedented global increase in the number of

Mineral Technologies Inc. - MODSIM

2010年10月27日 MODSIM™ powerful and versatile capabilities make it the perfect computer simulation tool for quarry operators, coal processors, base metal and industrial mineral producers, consultants and engineering firms in the mineral processing field. MODSIM™ is a very cost effective solution for circuit design and optimization.

《选矿厂设计》(Mineral Processing Plant Design)课程教学 ...

课程编号:0815210506MPPD. 《选矿厂设计》(Mineral Processing Plant Design)课程大纲. 课程56学时,3.5学分, 课程设计2周=20学时,2学分. 一.课程的性质、目的及任务. 本课程是矿物加工工程专业的专业主干课程之一。. 通过本课程学习,使学生初步掌握选矿厂设计

Minerals Processing Toolbox - AusIMM

Australian Mineral Processing Laboratory Capabilities. Metallurgical Testing Methods – General. Ex-Renison Tin Manual, PDF 303 KB (provided by Ron Goodman) Metallurgical Testwork for Plant Design. Metallurgical Process Development for Plant Design PDF 183 KB (by David Lunt, Ian Ritchie and John Fleay. From proceedings Mindev ’97, provided ...

Introduction to Mineral Processing or Beneficiation - Sepro

2018年1月12日 1.0 Introduction. 1.1 Mineral Processing and Extractive Metallurgy. Mineral processing is a major division in the science of Extractive Metallurgy. Extractive metallurgy has been defined as the science and art of extracting metals from their ores, refining them and preparing them for use. Within extractive metallurgy, the major divisions in the ...

Mineral Processing Plants Multotec

A mineral processing plant recovers or extracts minerals through a range of processes, including comminution, sizing, gravity concentration, magnetic separation, and more. Multotec offers the expertise, equipment and processes to create a plant of this kind, and with a uniquely optimised mineral processing plant design, this plant will have ...

Technology and innovation in mineral processing - AusIMM

2021年9月21日 effective and efficient engineering and design approaches, particularly as applied to gold processing plants in the late 1970s and 1980s. The nexus of the Australian “open approach” and a history of technical development has led to significant global penetration of Australian influence in innovation in a number of mineral processing areas.

Design, Capital and Operating Costs of Mineral Processing Plants

2007年4月27日 This paper reviews important aspects of the design of mineral processing plants, emphasizing the different factors which seem to be most important today, when labour and energy represent a high proportion of total costs. Such items as autogenous and semi-autogenous grinding, two-stage classification, large flotation cells, pressure filtration ...

Recent Progress on Data-Based Optimization for Mineral Processing Plants

2017年4月1日 The decision-making methods used for complex mineral processing often contain time-scale and space-scale decompositions of the global production indices, as shown in Fig. 1.First, the decision-making department of the plant determines the monthly global production indices, Q j (t m) (where j = 1, 2, , J, J is the number of global

Mineral processing plant design : Mineral Processing Plant Design ...

2022年7月30日 Mineral processing plant design by Mineral Processing Plant Design Symposium (1978 : Denver, Colo.) Publication date 1980 Topics Ore-dressing plants -- Design and construction -- Congresses Publisher New York, N.Y. : Society of Mining Engineers of the American Institute of Mining, Metallurgical, and Petroleum Engineers